What is Hemicell XT?

Hemicell is a patented energy sparing feed enzyme, with guaranteed final-feed potency, that breaks down β-mannans to completely prevent the inflammatory feed induced immune response, resultant waste of energy and other problems that this response causes.1,2

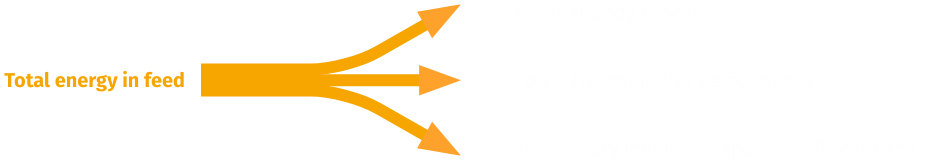

Without Hemicell XT:

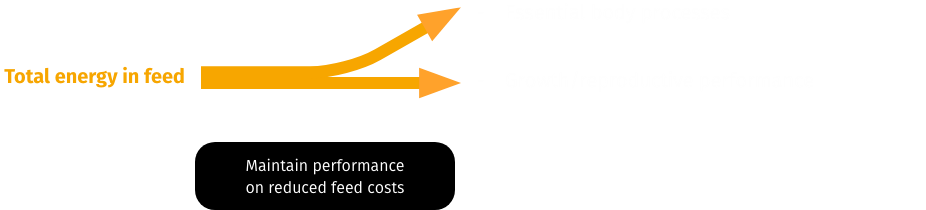

With Hemicell XT:

Used in-feed, with no withdrawal or restrictions when used in combination with other feed additives, Hemicell XT simply means less wasted energy and improved Intestinal Integrity, therefore reduced feed costs, improved animal health and better sustainability.

Not all feed enzymes are made equal…

Some feed enzyme products work by reducing fibre viscosity and improving performance via rate of passage through the gut. Others improve nutrient digestibility by “opening up” feed components the animal is unable to access on its own. These are considered energy-releasing enzymes.

Hemicell XT is different because it is an energy sparing enzyme. Rather than trying to find extra energy, it stops unnecessary, energy sapping processes taking place, so that everything available from the feed can be fully directed towards essential body processes, growth and production.

ß-mannans in feed…

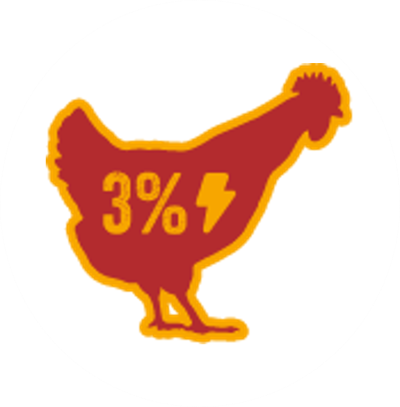

trigger an innate feed induced immune response

trigger an innate feed induced immune response waste up to 3% of the energy in feed1

waste up to 3% of the energy in feed1 more feed required to maintain growth and production

more feed required to maintain growth and production

Hemicell XT breaks down ß-mannans BEFORE they can trigger a feed induced immune response

Reducing Feed Costs

The no. 1 cost in food animal production is FEED and the most expensive component of feed is ENERGY

β-mannans consume of up to 3% of the energy in animal feed1

Equivalent to up to 90kcal/kg ME in broilers and 63kcal/kg NE in pig

Reducing Health and Environmental Costs

Hemicell XT optimises Intestinal Integrity2, which generates…

and translates into

By reducing the requirement for feed inputs, Hemicell XT contributes to reducing the global demand for feed ingredients.

Frequently Asked Questions

Find out more about Hemicell XT

- Daskiran, M., Teeter, R., Fodge, D. and Hsiao, H. 2004. “An Evaluation of Endo-ß-D-mannanase Hemicell) Effects on Broiler Performance and Energy Use in Diets Varying in ß-mannan Content.” Poultry Sci. 83: 662-668.

- Poulsen, K. Effects of Hemicell on Intestinal Health in broilers analyzed in 44 Experiences. Data on file.